Ammunition Solutions

On The Horizon

Our Expertise

Ammunition Manufacturing

Our 155mm+ Presses — On the Front Lines of Defense

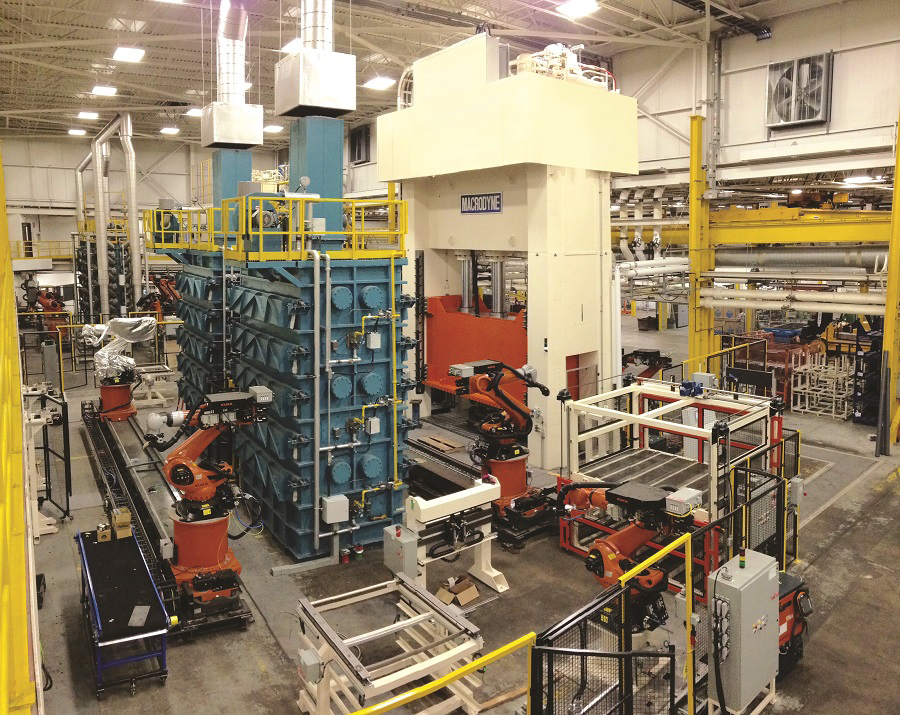

Currently, U.S. munitions plants are facing record demand for 155mm artillery shells and other large-caliber rounds. Programs like the 155mm production expansion are now driving urgent retooling to increase monthly output. Our presses are already powering automated 155mm shell lines, delivering 15,000+ shell bodies/month with zero acceptance test failures and top-quality outputs.

OUR ADVANTAGE

Built in the U.S. — Means Compliant, Fast & Ready to Engage.

Our press and automation systems are built domestically and proven in active defense production lines. This assurance of U.S. support, zero-risk integration, and demonstrated delivery at scale sets us apart from our competitors who rely on offshore assembly or who don’t reliably deliver on expedited schedules or critical delivery timelines.

Macrodyne Presses

Advanced Weaponry & Ammunition Presses

Macrodyne hydraulic presses support the manufacturing of shells, cartridge cases, warhead casings, and propellant components, providing the force and accuracy needed to meet demanding military standards.

These systems enable high-volume, repeatable output for critical munitions, ensuring reliable supply and safe, proven performance across a range of defense applications.

Ammunition

WEAPONRY & AMMUNITION

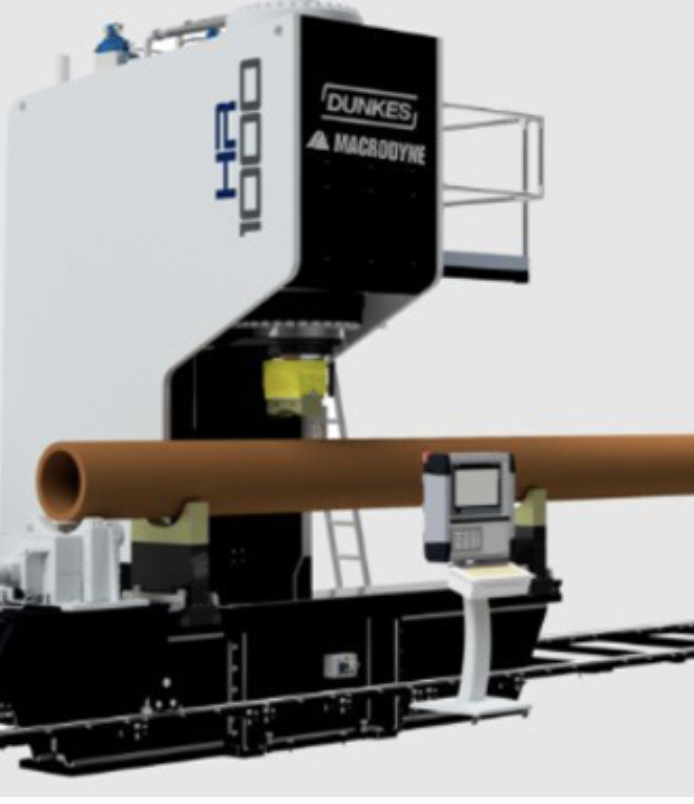

Heavy Artillery Barrels

Straightening Press

WEAPONRY & AMMUNITION

At a Glance

Industry Need:

Large-caliber projectiles like 155 mm shells require immense forming force and precise control to ensure uniform wall thickness and structural integrity. Reliability is critical for munitions that must withstand extreme explosive forces.

Our Capability:

Macrodyne high-tonnage forging and deep-draw presses deliver the power and accuracy needed to form steel shell bodies to rigorous defense standards. Our proven systems are already supporting high-volume 155 mm shell production in North America.

Industry Need:

Ammunition manufacturers need high-speed, consistent production of cartridge cases for rifles and cannons, with efficient throughput and minimal downtime.

Our Capability:

Macrodyne’s hydraulic presses, paired with automated press-to-press transfer systems and quick die change technology, enable efficient, repeatable cartridge case forming. This increases output while lowering integration risks and labor requirements.

Industry Need:

Complex components like bomb casings, missile warhead jackets, and mortar shells demand heavy presses capable of shaping intricate geometries while maintaining accuracy and safety.

Our Capability:

Macrodyne dishing presses (up to 3,500 tons) and compression molding systems are engineered to handle these demanding applications. Our equipment forms precise, high-strength components that meet stringent defense tolerances.

Industry Need:

Propellant grains and explosive charges must be pressed with extreme accuracy and safety to maintain performance and stability under operational conditions.

Our Capability:

Macrodyne designs custom extrusion and compaction presses with safety enclosures and precise force control for pressing and extruding propellant. These systems combine performance, repeatability, and operator safety.

Industry Need:

Small but essential components like primer cups and fuzing elements require high consistency, automation, and safe handling during production.

Our Capability:

Macrodyne integrates high-speed presses with automated feeders and robotic handling, ensuring repeatable production of small components while reducing manual labor and minimizing risk.

Industry Need:

Out-of-life ammunition must be safely and securely destroyed without environmental or operational hazards.

Our Capability:

Macrodyne cryofracture presses provide a proven, safe method for breaking down munitions. Our systems enable arsenals and contractors to meet demilitarization requirements reliably and efficiently.

Whatever Press & Automation You Need — Macrodyne Stands Up to the Toughest Conditions with World-Class Precision

Call us to learn more about how our advanced press solutions can be customized to suit the exacting standards and strict requirements of defense and military operations.

More Ways Macrodyne Can Deliver Robust Solutions:

- Blanking & Punching

- Cold Forming

- Cryofracture

- Straightening

- Trimming

- Bulge Forming

- Compaction

- Elastoforming

- Stretch Forming

- Tube Swaging

- Closed Die Forging

- Compression Molding

- Deep Draw

- Extrusion

- Hot Forging

- Dishing

- Forging

- Hot Stamping

- Open Die Forging

- Research

Let’s Team Up to Craft Your Ammunition Manufacturing Solution

APPLICATION HIGHLIGHT

Big Projects — Serious Capability

Our Proven Results

- Texas, USA

155mm Shells, UNION “Factory of the Future”

Two fully automated 155 mm press lines with billet cutting, forging, machining, painting, inspection, and digital tracking.

in their own words

“Building a factory from a clean sheet is a chance to do it right. That’s why UNION picked Macrodyne for the most crucial process in our factory: our forging equipment.”

Russell Varone - Head of Factory Operations at UNION

A macrodyne & union partnership

The U.S. defense sector reached a major milestone with the official construction launch of UNION’s new production facility, ‘Factory 1’ in Texas, USA.

Once fully operational, the facility, aptly called the “Factory of the Future”, will house two identical, fully automated Macrodyne USA Inc. press lines, significantly strengthening US 155mm manufacturing and rebuilding critical domestic and global stockpiles.

video highlight

Meeting the Demands of the Defense Industry

APPLICATION HIGHLIGHT

Supporting New Allied Defense Targets

Our Proven Results

- Ingersol, ON Canada

155mm Shell Bodies, IMT Group Facility

in their own words

Chip Hayden, VP of Kinetics and Energetics Systems at Regulus Global

a MACRODYNE & imt group partnership

The newly commissioned production line is equipped with advanced automation and digital data capture, ensuring flexibility and precision in meeting the U.S. Army’s needs for M795 and M1128 rounds.

This facility plays a crucial role in the collective effort to bolster the U.S. Army’s 155mm artillery production to 100,000 rounds per month by 2026, enhancing defense readiness. At Macrodyne, we’re honored to be a vital contributor, supporting the innovation and strength that this initiative represents.

Manufacturing Locations

Our Strategic Manufacturing Facilities

USA

Primary Facilities

- Connecticut, USA

- Illinois, USA

Canada

Facility

- Ontario, CAN

Mexico

Facility

- Aguascalientes, MEX

Germany

Facility

- Stuttgart, GER