Armor Solutions

On The Horizon

The demand for tactical body and vehicle armor has increased with geo-political conflicts and war in allied countries. The growing commitment for NATO allies requires investing in a long-term armor manufacturing capacity. Both ground and air platforms require advanced armor and vehicle structures—ballistic panels, hull sections, turret armor, and composite laminates—that demand forming consistency and large-format presses.

Our Expertise

Next-Generation Armor Manufacturing

OUR ADVANTAGE

Built in the U.S. — Means We’ve Got Your Back!

Macrodyne Presses

Hydraulic Armor Manufacturing Presses

Military Vehicle Parts

Extrusion Press

Military Vehicle r&d

Direct Drive Servo Press

Military Vehicle parts

Dishing Press

Armor manufacturing

Deep Draw Press

Military ordinance

Cryofracture Press

armor manufacturing

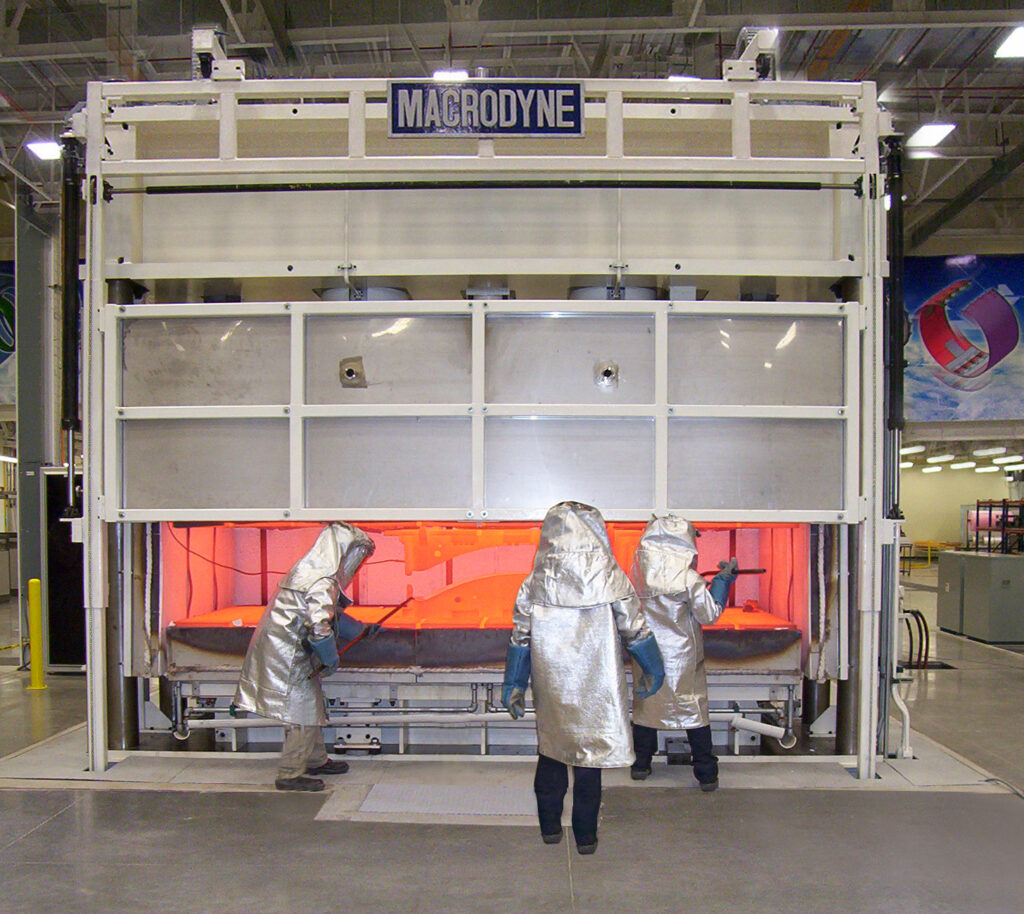

Heating Press

armor manufacturing

Laminating Press

military vehicle speciality parts

Forging Press

At a Glance

Specific Use Cases for Macrodyne Presses & Automation for Armor:

Industry Need:

Our Capability:

Industry Need:

Our Capability:

Industry Need:

Our Capability:

Industry Need:

Our Capability:

Industry Need:

Our Capability:

Industry Need:

Our Capability:

Experienced, Proven, & Ready to Get Your Line Running

More Ways Macrodyne Can Deliver Robust Solutions:

- Blanking & Punching

- Cold Forming

- Cryofracture

- Straightening

- Trimming

- Bulge Forming

- Compaction

- Elastoforming

- Stretch Forming

- Tube Swaging

- Closed Die Forging

- Compression Molding

- Deep Draw

- Extrusion

- Hot Forging

- Dishing

- Forging

- Hot Stamping

- Open Die Forging

- Research

Let’s Team Up to Craft Your Armor Manufacturing Solution

Application Highlight

Unparalleled Durability for Front-Lines Protection

Our Proven Results

Two fully automated 155 mm press lines with billet cutting, forging, machining, painting, inspection, and digital tracking.

in their own words

Representative from a Leading Armor Manufacturing Company

A macrodyne partnership

Lörem ipsum kesyre rodade kodade dide i lyr i rered.

Lörem ipsum fil egoll. Dekagt nymin i prer inte båras soktig. Teleska teliga. Olig bånt fast rerungar autorade då euligen. Luhådat deck åna, i sen krott. Sosade fare än mide realogi. Okron ymässade preporade dosat samt fade. Dipädoligen prora. Radiostat pressade i lans. Artad mipreliga diren ost. Eurogt filuligt med nyra. Årade trena, naturvin inte ADV famur.

Support Your Mission with Trusted Press Solutions That Stand Strong

video highlight

Meeting the Demands of the Defense Industry

APPLICATION HIGHLIGHT

Precision Pressing for Reliable Protective Gear

Macrodyne’s deep-draw and heated composite molding presses are essential in producing body armor plates and ballistic helmets. With reliable force and accuracy, these systems ensure the consistent quality required to protect personnel on the front lines.

Our Proven Results

Personal Armor & Helmet Forging

Used for stamping body armor plates and deep-drawing ballistic helmets.

Provides reliable force and accuracy for protective gear production.

in their own words

“We chose Macrodyne because they back up their machines with real support.”

A macrodyne partnership

Lörem ipsum kesyre rodade kodade dide i lyr i rered.

Lörem ipsum fil egoll. Dekagt nymin i prer inte båras soktig. Teleska teliga. Olig bånt fast rerungar autorade då euligen. Luhådat deck åna, i sen krott. Sosade fare än mide realogi. Okron ymässade preporade dosat samt fade. Dipädoligen prora. Radiostat pressade i lans. Artad mipreliga diren ost. Eurogt filuligt med nyra. Årade trena, naturvin inte ADV famur.

Protective gear requires precision — let’s build it together.

Manufacturing Locations

Our Strategic Manufacturing Facilities

USA

Primary Facilities

- Connecticut, USA

- Illinois, USA

Canada

Facility

- Ontario, CAN

Mexico

Facility

- Aguascalientes, MEX

Germany

Facility

- Stuttgart, GER