Aerospace Solutions

On The Horizon

With growing military air traffic, national security concerns and strategic government investments, the skies in North America are changing. From next-generation aircraft to drones, supporting these sectors depends on titanium, aluminum, and composite parts formed under strict tolerance with precision.

Our Expertise

Aerospace & Drones Manufacturing

OUR ADVANTAGE

Macrodyne Presses

Advanced Aerospace & Production Presses

From aircraft fuselage panels to landing gear components, our presses for aerospace manufacturing integrate elastoforming, fluid cell forming, superplastic forming, composite molding, forging and more, delivering flawless accuracy with every press cycle.

Advanced Aerospace & Production Presses

Elastoforming & Fluid Cell Forming Press

Aircraft Components

Aircraft Components

Stretch Forming Press

Aircraft & UAV/Drone Components

Hydroforming Press

Aircraft & UAV/Drone Components

Forging Press

Aircraft & UAV/Drone Components

Stamping Press

Aircraft & UAV/Drone Components

Deep Drawing Press

Aircraft & UAV/Drone Components

Compression Molding Press

At a Glance

Industry Need:

Our Capability:

Industry Need:

Our Capability:

Industry Need:

Our Capability:

Industry Need:

Our Capability:

Industry Need:

Our Capability:

At a Glance

Our Full Range of Composite Material Molding & Forging for Military & Aerospace Components:

Structural & Aircraft Components

Aircraft Interior & Secondary Structure Components

Landing Gear & Structural Supports

Propulsion & Engine Components

Actuator Housings and Brackets

Turbine Engine Rings / Blades

We’re the Experts. We’ve Done It Before — And We’re Ready to Do It Again

Call us to learn more about how our advanced press solutions can be customized to suit the exacting standards and strict requirements of your defense and aerospace projects.

More Ways Macrodyne Can Deliver Robust Solutions:

- Blanking & Punching

- Cold Forming

- Cryofracture

- Straightening

- Trimming

- Bulge Forming

- Compaction

- Elastoforming

- Stretch Forming

- Tube Swaging

- Closed Die Forging

- Compression Molding

- Deep Draw

- Extrusion

- Hot Forging

- Dishing

- Forging

- Hot Stamping

- Open Die Forging

- Research

Let’s Team Up to Craft Your Aerospace Manufacturing Solution

Application Highlight

Superplastic Forming — We’re Using a Ground-Breaking Patented Solution to Push Aerospace Higher

With a high strength-to-weight ratio and corrosion resistance, this disruptive advancement is ideal for the demands of aerospace applications, pushing past the boundaries of conventional superplastic forming, allowing for dramatically more geometrically complex parts, with higher quality and lower costs.

Our Proven Results

Patented Gas Oscillation Enhanced SPF enables faster, higher-quality forming of titanium and aluminum aerospace parts.

Cuts cycle times ~50% and expands geometric complexity.

in their own words

Andrew Powdrill, Forming Process Owner at ITP Aero

A macrodyne partnership

ITP Aero, a global leader in aero components for commercial and defense, partnered with Macrodyne to implement a GO-SPF press to reduce titanium thinning versus conventional SPF. CAD-based trials showed clear gains, so the team moved ahead to cut non-conformances, boost throughput, and reduce post-processing while holding thickness for tighter tolerances and higher yields. Led by Forming Process Owner Andrew Powdrill, the effort delivers results now and opens the door to lighter, more intricate designs in the future.

Whether you are new to the SPF process or represent a company with extensive experience with the application, we encourage you to contact us today.

video highlight

Meeting the Demands of the Defense Industry

APPLICATION HIGHLIGHT

Reaching the Skies — With Higher Volume Production

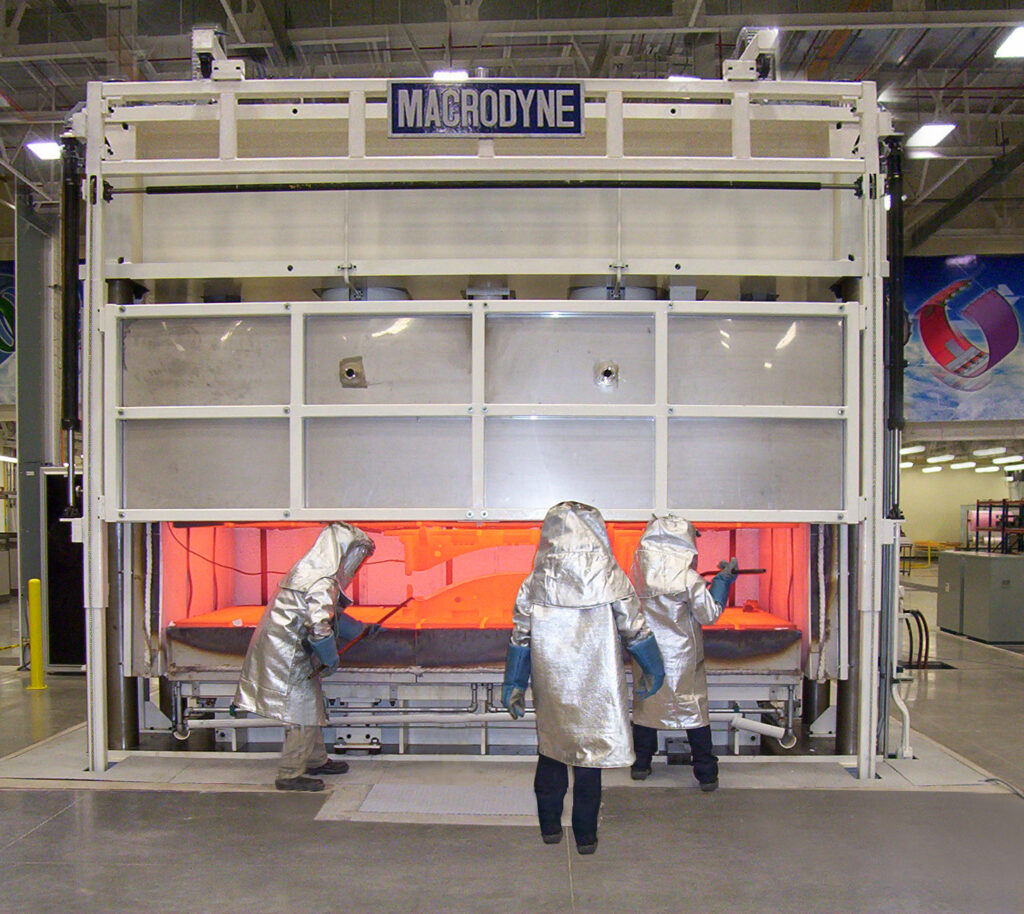

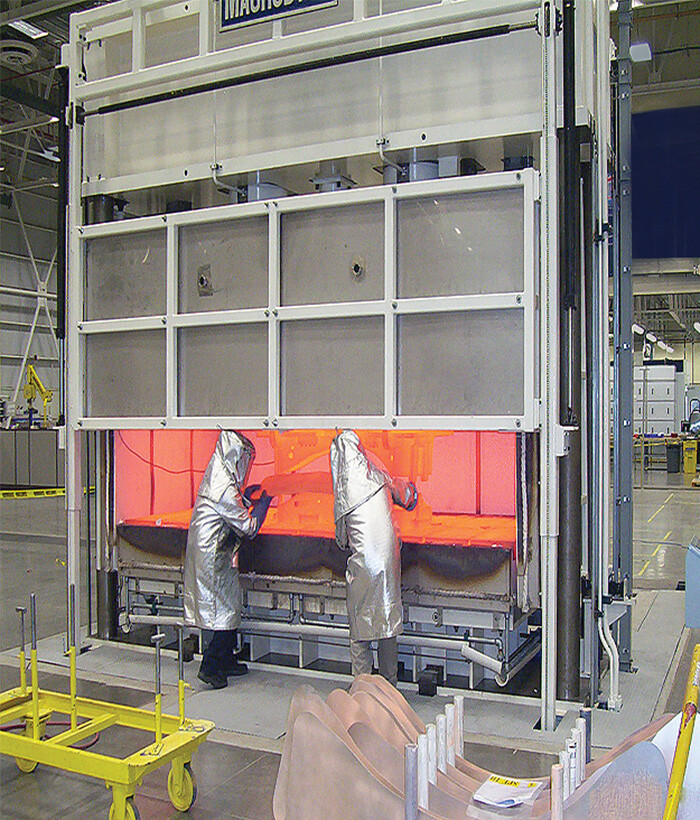

A Macrodyne hydraulic compression molding press is designed for the high volume production of molded components ranging from small thin, precision parts to large thick parts featuring a myriad of intricate shapes. Fast pressing cycles ensure maximum production output and prevent residual stresses in the parts, resulting from material viscosity increases during the composite press’s closing.

Our Proven Results

Composite Molding for Aerospace Engines

100-ton composite molding presses with multi-zone heated platens.

Press lines for forming jet engine thermal insulation composites with precision and repeatability.

Ensures lightweight, heat-resistant components for engine nacelles.

in their own words

Leading aerospace OEM

A macrodyne partnership

Lörem ipsum kesyre rodade kodade dide i lyr i rered.

Lörem ipsum fil egoll. Dekagt nymin i prer inte båras soktig. Teleska teliga. Olig bånt fast rerungar autorade då euligen. Luhådat deck åna, i sen krott. Sosade fare än mide realogi. Okron ymässade preporade dosat samt fade. Dipädoligen prora. Radiostat pressade i lans. Artad mipreliga diren ost. Eurogt filuligt med nyra. Årade trena, naturvin inte ADV famur.

Bring us your requirements. We’ll build the solution.

Manufacturing Locations

Our Strategic Manufacturing Facilities

USA

Primary Facilities

- Connecticut, USA

- Illinois, USA

Canada

Facility

- Ontario, CAN

Mexico

Facility

- Aguascalientes, MEX

Germany

Facility

- Stuttgart, GER